MBBR - Moving Bed Biofilm Reactors for Wastewater Treatment

MBBR - Moving Bed Biofilm Reactor

is derived from the Conventional Activated Sludge Process. It

utilizes suspended growth activated sludge process and fluidized

attached growth biofilm system.

Packing media (carriers) with large surface area is used in aeration

tanks and biofilm growth will take place around and inside the

packing materials. Due to the large surface area provided by the

suspended packing media, the MBBR process is able to take higher

BOD/COD loading.

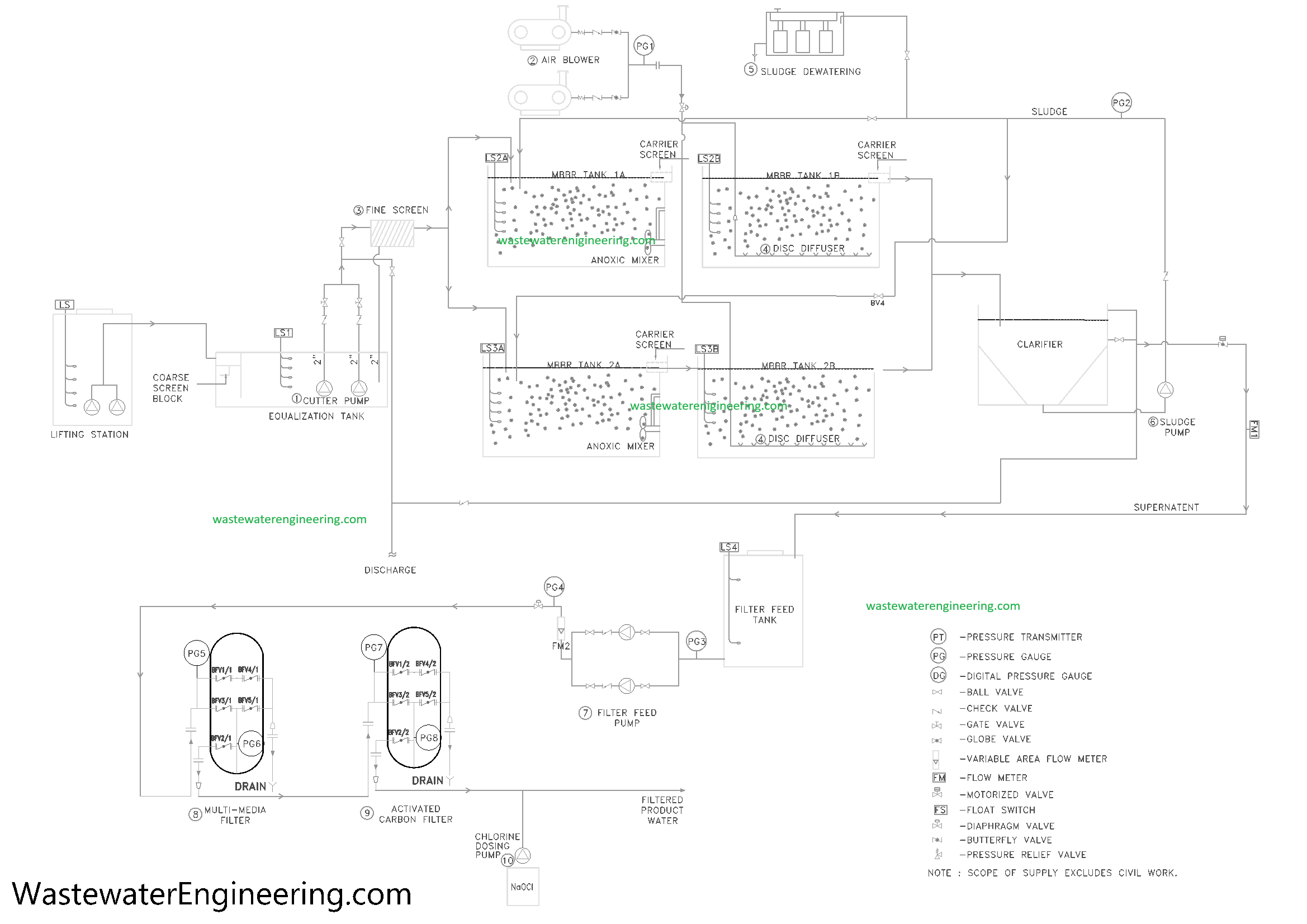

The following is a MBBR Design Schematic Process Flow Diagram (PFD), or Piping & Instrumentation Diagram (P&ID)

MBBR technology is a good choice for upgrading/retrofitting existing

activated sludge plants to achieve higher capaicity and better

effluent quality.

To prevent the suspended packing used in the MBBR reactors from

going into the downstream clarifiers, screens are usually required

at the exit to the clarifier. Air-lift pumps may also be used

to recirculate the suspended packings back to the front section

of the reactor.

The advantages of MBBR is it increased the BOD and COD loading in the same reaction tanks. It also has same flexibility to add Denitrification and even Anaerobic functions for nutrient removal. However the disadvantage is its final effluent quality is still much dependant on the settling tanks downstream. Thus it is usually necessary to add post-treatment using filters to polishing the treated water if reuse is required.

|